Last week I visited our frame builder in Taiwan and was able to gain a lot of insights into production, which I naturally don’t want to withhold from you along with a few insights into veloheld.

As we ourselves are a small manufacturer in terms of volume, we are pleased to be able to work with a frame manufacturer that is not huge either. However, as a second-generation family business with 26 employees, our ideas of a perfect steel frame can also be realized to a high standard in smaller quantities. We only have around 30 – 130 frames built per model and currently have around 400 frames handmade there each year.

How does the development process lead up to the finished frame? From the initial idea to the finished technical drawing, we work closely with the frame builder, as often not all the ideas we come up with can be realized. Some examples of possible questions that may arise:

In which radii can tubes be bent? Is there a corresponding bending form for this or does it have to be produced first? Do the pipes need to be reinforced at certain points in order to better counteract loads or possibly allow cable openings in the pipe? Which pipe qualities are possible and how long are the delivery times for these pipes, especially if they come from brand manufacturers such as Reynolds or similar?

These and other questions can only be answered together with the frame builder. Once this has been clarified, the technical drawings can be produced in the various frame heights and finally checked and approved by us before the start of the prototype or production. Now the frame builder begins to order the tubes or use chrome-molybdenum tubes in stock. We usually use a so-called 25CrMo4 or 4130 CroMoly alloy in the form of double end-reinforced tubes, i.e. with thicker walls at the ends, in order to provide the more “stressed” transition and welding areas with sufficient strength. These tubes are a perfect combination for the best riding characteristics (stiff, but still comfortable), weight, price, sustainability and also relatively quick availability. They are supplied by Taiwanese manufacturers and can also be “branded” under the name Reynolds (Reynolds 520 or Reynolds 525, as with the new veloheld.alley). We do not use tubes (as in the picture) that only have one wall thickness (so-called plain gauge tubes).

For the new veloheld.lane stnlss model, we are venturing into stainless steel for the first time this year. This very expensive and not so readily available material pushes the specific properties of steel even further into special “spheres”. The manufacturer of these pipes (KVA) only supplies them from the USA. After the specific shaping of the pipes, they still have to be heat-treated to give them perfect strength. A lengthy process and therefore the frames are also more expensive.

Once all questions about the material and geometry have been clarified, production can begin: Tubes are cut to length and “notched” for a precise fit, shaped if necessary and joined together. This is done in optimized individual steps, e.g. the rear struts and dropouts are shaped and connected according to the drawing and only later welded to the main frame.

The main frame is also first “spot-welded” in the frame jig and only later properly welded with the addition of shielding gas (TIG or American TIG).

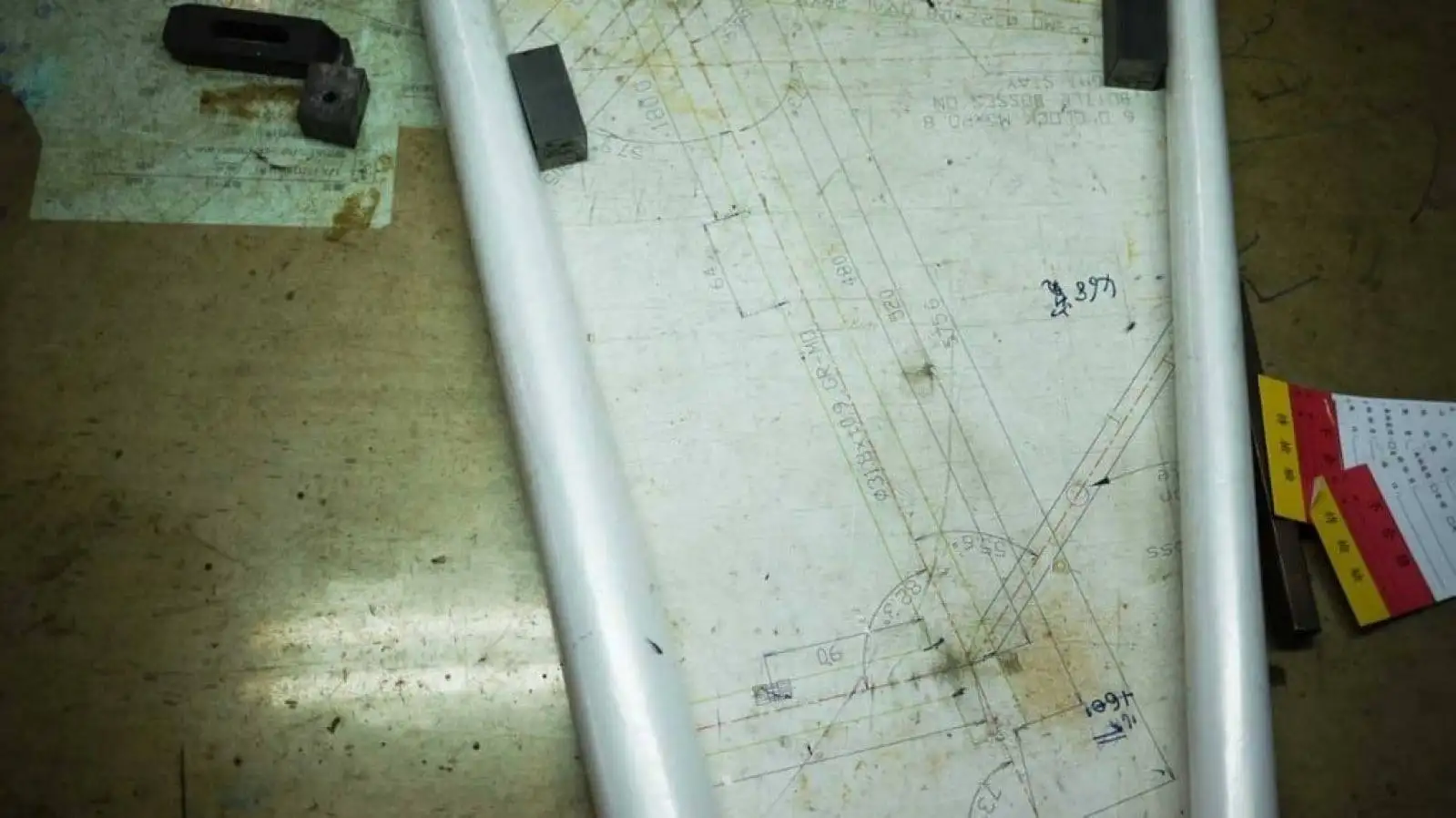

For checking purposes, compare with the technical drawing on a scale of 1:1. Once the frame is finished, an EN test is carried out to determine the required European safety standards. This takes place before actual production, using prototypes that are true to series production. The test can be carried out directly on site in our frame manufacturer’s internal test laboratory. Other manufacturers also use this, as you can see from the aluminum frame in the picture.

Once the frames have been produced, they are protected against corrosion by an external service provider using a special dip coating process. This is usually black semi-matt and also serves as a primer for subsequent paintwork or powder coatings. However, this corrosion protection can also be very decorative, as in the picture below. Here Jack is holding a frame that looks more like a chrome coating. However, it has also been coated with a cathodic dip coating.

The final step is painting, which is again carried out by an external service provider. Most of our series frames are wet-painted and decorated directly in Taiwan. Frames that you order in a special color will of course be powder-coated and decorated on site in Dresden. Below pictures after painting the new frames.

Production is of course even more complex in various respects. But I hope I was able to give you a little insight. If you have any questions, I look forward to your comments.