This has now taken a little longer than planned. But now we can present you the new veloheld.icon Allroad road bike, which we already announced in our frame building article.

As we were not yet satisfied with many of the details, there were a few extra loops in the development process. Because this frame has hardly anything in common with the previous veloheld.icon. New geometry, new tubes, 3D-printed dropouts and, most importantly, production on site in our own frame construction workshop make the frame truly something special, for which it was more than worth going the “extra mile” in development.

The concept behind the bike

The veloheld.icon is the sporty road counterpart to our gravel bike veloheld.iconX. But here the focus is more on the asphalt. But don’t worry, it doesn’t always have to be the very best. No, the relaxed, sporty endurance geometry, the naturally damping Columbus tubeset and the tire clearance of up to 34 mm allow you to fly over poor roads or even fine gravel tracks. So you and the bike are perfectly prepared for light and fast bikepacking tours or long-distance races.

The details of the frame

Until now, our gravel bike and the previous allroad bike didn’t have much in common, and as the frame had been due for an overhaul for a long time, we used this opportunity to bring the family a little closer together.

This bike also has a comfortable yet sporty geometry. With longer head tubes and slightly shorter top tubes, the frame is ready for long days in the saddle.

The new veloheld.icon Allroad frame now also has the same head tube shape as the veloheld.iconX gravel bike. In our eyes, this

“tapered” shape of the head tube

fits better with the slim and elegant Columbus tubes of the main frame than the continuous 44 mm “head tube cans”. These tubes don’t look particularly good, especially with larger frame heights. The “thinner” road tires always stand in contrast to this. In our opinion, these tubes fit much better on an MTB. And another detail not to be underestimated – your Chris King or a similar anodized headset will of course look even better this way than half hidden in the 44 mm head tubes.

The cable routing is also internal, as on the gravel bike, but with this new frame we go one step further. The brake cable routing is internal from the down tube to the chainstay exit. This is where a larger

T47 bottom bracket

which also provides more stiffness when pedaling.

And we really thought long and hard about possible circuits. Will there still be mechanically controlled groupsets in this segment in the future? In the end, we decided to offer a routing for classic mechanical cable guides (Shimano 105 or Campa groupsets) in addition to the basic version of the Di2/AXS cable routing, as not everyone finds this form of shifting so great.

What we definitely didn’t want here was a prepared down tube for mechanical groupsets, i.e. 2 inlets on the down tube, whereby the unused openings are closed with a “cover” when electronic shifting is installed.

We offer you here two different frames variant 1 with an opening on the down tube only for the brake cable when using electronic shifting and another variant with two openings, where you can elegantly route the shift cables to the bottom bracket exit and through the chainstay to the dropout. This is the more elegant option, especially for individual, classic setups with mechanical Campagnolo gears.

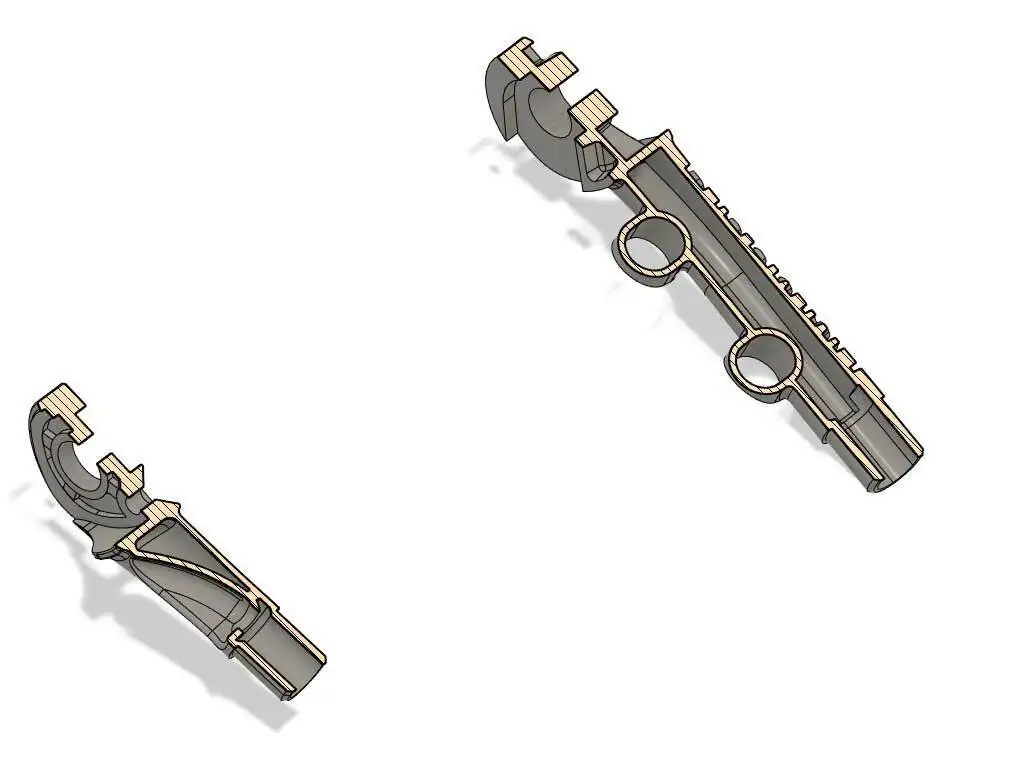

The highlight of the frame is undoubtedly the

3D-printed stainless steel dropouts

. You’ve probably already heard of 3D printing and we don’t need to tell you much about it. That’s why I’ll only give a very brief explanation here. The process is called selective laser melting or SLM. Stainless steel powder is melted in layers by a laser, forming the dropouts layer by layer. The optical quality and stability are identical to cast components. A huge thank you for the realization of the dropouts and the frame in general goes to the industrial designer Markus Trappe!

The production

The veloheld.icon is the first frame to be manufactured in our new frame production facility near Leipzig. When selecting the pipes, we compared Reynolds, Dedacciai and Columbus and finally decided on Columbus pipes. The pipe specifications from this traditional manufacturer were simply perfect for our requirements and the communication with the Columbus team is simply great.

Of course, the start was also fraught with minor difficulties. For example, there was no digital data for the Columbus chainstays, so we first had to find out how to connect them to the printed chainstays by carrying out a few tests.

The very first frame was also produced under time pressure for the Craft Bike Days and was still a pre-production model. Of course, not all the weld seams were perfect. We still had to test how we could attach the 3D printed dropouts to the chainstays and seatstays. Soldering or welding? These are now welded and partially ground.

We were also not yet satisfied with the quality of the wet painting, which is also done here on site. Different layer thicknesses required different pre-treatment. As we always powder-coat our other frames, wet painting was also new territory.

But that’s why we make prototypes! But now we can proudly say that we have been able to perfect all the details for ourselves and that the production at our frame builders Sören and Lukas, as well as the paintwork, is running exactly according to our ideas.

The extra mile was more than worth it and we are now looking forward to seeing the veloheld.icon with you on the good and bad roads out there!

Here you can see for yourself and take a closer look at the frameset and the complete bike.

Do you still have unanswered questions? You are welcome to contact us here or via the other contact options!