We can finally get started! With the current establishment of our own bicycle frame production, a long-awaited wish of ours is coming true. In the following text we give you many insights into our new in-house production.

Until now, the veloheld frames have been manufactured in Taiwan by a very experienced frame builder and his team according to our designs. We reported on this here a few years ago. This was not a problem for a long time, because the quality was great and the delivery times were ok. As you probably know, the vast majority of bicycle components come from Asia and so we were able to import not only our frames but also gear groups, stems, handlebars, seat posts and other parts. As much as we wanted to act more sustainably here in terms of regional production, this was the fact that we had to face up to.

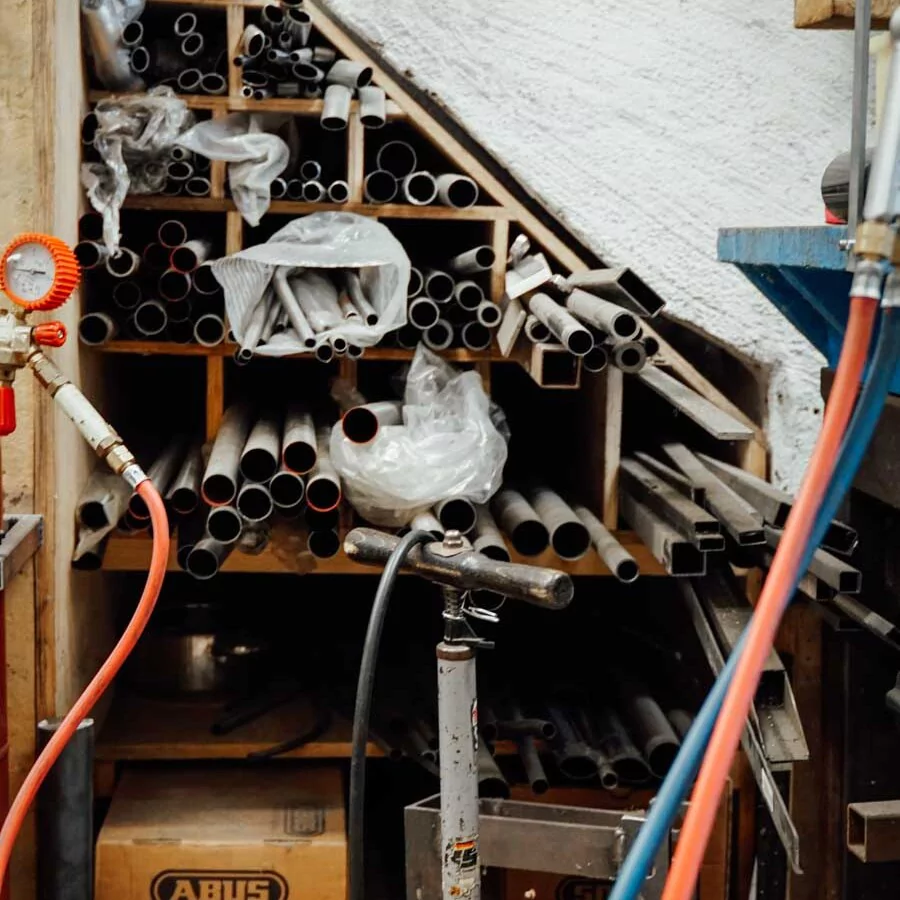

However, as we all know, the “world situation ” has changed so rapidly and profoundly in recent years that the prices of raw materials, in our case the chromoly tubes for frames and forks, have skyrocketed. With further increases in transportation, we came to the point where it no longer made sense in terms of costs to have all frames manufactured in Taiwan.

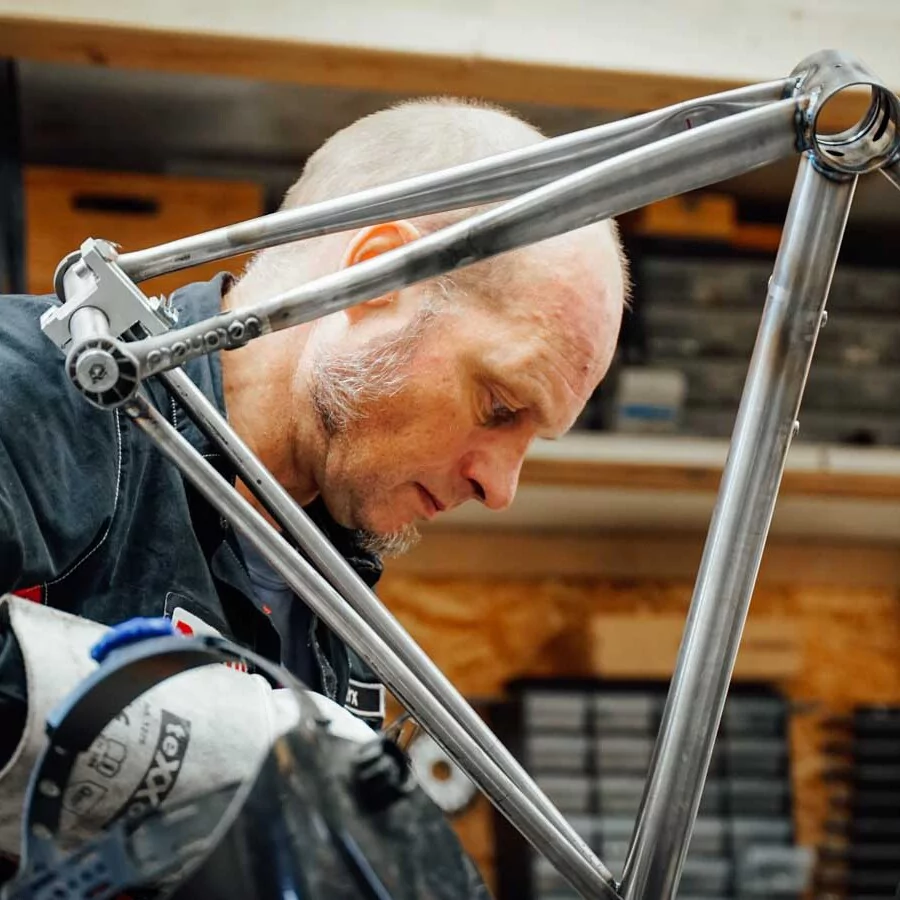

During this time, we were lucky enough to come into closer contact with the Leipzig frame builder Sören Marx. Sören is no stranger to custom bikes, as he was known for his frame building company Unique Cycles in our region and beyond. We were already working together on some smaller projects when he decided to turn his profession into more of a sideline. This is where we became active and took the opportunity to bring Sören into the veloheld team!

The starting point of this new chapter in the veloheld story will be the new veloheld.icon Allroad Bike. The first model that we will manufacture completely ourselves “Made in Germany” or “Made in Leipzig”.

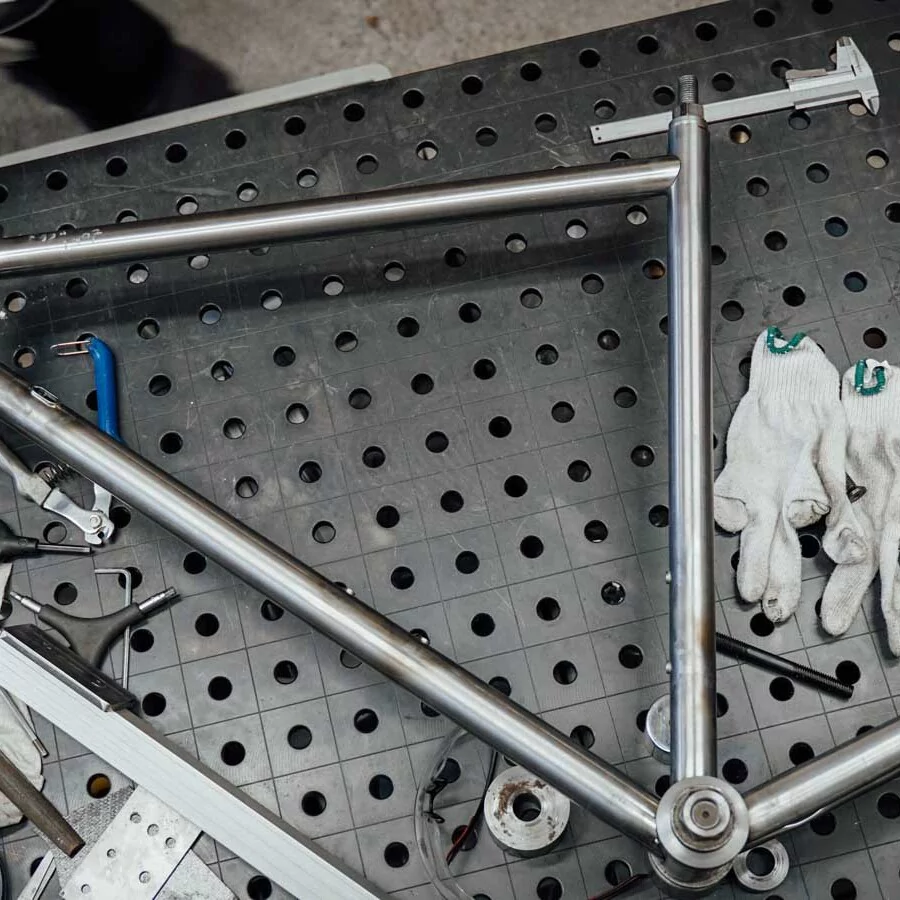

We have completely revised the veloheld.icon with the help of our developer Markus Trappe. Stainless steel 3D printing was used to create the dropouts for the prototype. For the series frames, however, we will switch to a cast mold for the dropouts, as 3D printing technology is still very expensive and other production methods are more efficient for series production. Despite its increasing use in bicycle frame construction, we believe that this technology is more suitable for prototype construction or for the rapid realization of special parts. Incidentally, the main tubes come from Columbus and are manufactured in Italy.

Here in the video we show you a few short excerpts of the creation.

What are the next steps in veloheld frame production?

Production of the veloheld.icon Allroad frames will start shortly. The prototype enabled us to gather a lot of knowledge for the upcoming series production. We will of course keep you up to date here.

The next project, the new veloheld Pinion frame, is already being launched at the same time. With the experience we had with our first Pinion frames, we are planning an alternative tensioning option for the belt. Stay tuned – the details will follow here too!

And pssst, there is also a veloheld cargo bike, which will also be manufactured by us. As you can see, there are a lot of great projects planned and we are really looking forward to realizing them all for you with our own hands!

In order to realize all these new projects, Sören will receive support from the next frame construction talent Lukas in February 2023. We will also be moving into larger premises in the coming year.

As you can see, we are already very excited and can’t wait to start all the projects!

Do you have any questions or ideas for our frame construction team or for new projects? Then let us know and send us a message directly as a post or as an e-mail.